3 Reasons Why It’s Taking So Long to Get Your New Furniture

August 10, 2021

COVID-19 took our lives and turned them upside-down, and not a single business was left unaffected. Very quickly into quarantine, it was obvious that the pandemic would affect much more than how I’d safely interact with the homeowners I advise, my on-hand contractors and internal team. COVID’s touch reached deep into the home improvement industry in ways none of us could foresee.

If you’ve noticed a shortage of your favorite products this past year or an insanely lengthened expected delivery time on a new piece of furniture you purchased, then you know exactly what I’m talking about.

But why is this happening? And how do we bypass this issue?

You deserve answers to these questions, so let me break it down for you.

1. Many of the Products You’re Buying Rely on Foam

When COVID hit, no one truly anticipated the rise in demand in bedding and furniture that would take over the home design industry.

With nearly 58% of the world confined to their homes to prevent the spread of COVID, there was a significantly high rise in demand for all kinds of products - food, clothing or (you guessed it) furniture. The frustration and urgency to claim those products in a timely manner was felt across the world.

The largest foam and fluff items we own - our beds, couches, chairs, comforters - ended up taking over the vast majority of products people wanted to change in their homes.

But nothing can just work itself out in the end when it comes to a pandemic, right? Thus began the ever-toppling domino effect of foam shortages across the nation.

2. The Production of Chemicals Needed to Produce Foam Came to a Halt

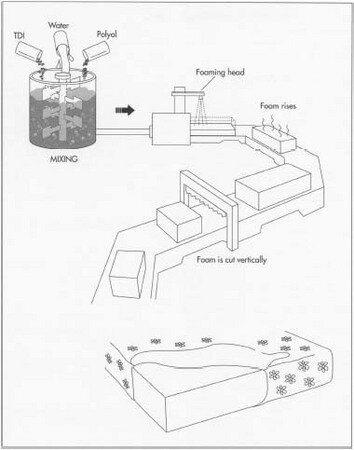

Foam production

Our foam products are manufactured using a variety of chemicals, two of which are polyol and toluene diisocyanate (TDI). Factories use large quantities of these chemicals to create the foam you may be lounging on right now and they rely on the regular and timely delivery of these chemicals through mobile tanks that journey across the country to multiple foam plants.

Because the industry that organizes the transportation of goods is also suffering from a shortage of drivers and an excess of goods that need to be transported, these foam plants don’t have the ingredients they need to create the foam products in high demand.

The plants do not keep these chemicals on-hand. This onlymakes sense; you wouldn’t expect a gas station to have an endless supply of gasoline on hand in the back room.

Now, back to our good friend polyol. Polyol is typically made from three raw ingredients, one of which is called propylene oxide (PO). Stay with me here; the boring part is almost over!

PO makes up the majority of the recipe for polyol. But at the start of the pandemic, many PO producers held off on production because they couldn’t foresee the demand for the product. Instead of producing too much PO, they wanted to hold off long enough to see if it would be needed at all in a pandemic.

In June of 2020, PO producers realized there was a spike in furniture demand and kicked production into gear, trying desperately to make up for lost time. This caused a delay in polyol production that the PO producers simply could not keep up with.

But wait, it gets better… or worse, I guess.

3. The 2021 Texas Winter Storm Was the Final Blow

PO is produced in five major plants in the United States: one in Louisiana and four in Texas. If you kept up with Texas news earlier this year, you may know where I’m headed with this…

Texas can prepare itself for a hurricane, as those are commonplace storms for the state. But a week-long winter storm? Not a chance.

Historic Texas winter storm, 2021

Texas chemical plants have plans in place for hurricanes, often shutting off production until the storm passes. But the winter storm was the curveball Texas businesses were not expecting. Chemical plants suddenly lost power, in turn losing essential materials for the production line, such as steam, nitrogen and hydrogen.

This was a major hit for chemical plants. Damage and progress was assessed day-by-day, yet the likelihood of starting up production at full-capacity was very low. Many of these plants are still trying to fully recover.

So, What Does This Mean?

What does this mean for that new couch you’ve had your eye on for months?

First, allow me to say that I truly empathize with this struggle. I am advising and collaborating with homeowners who are currently waiting 22 weeks for a custom-made piece. Their forever homes are put on hold all because shipping times and a lack of access to building materials came into play, and don’t get me started on the spike in cost. My frustrations are their frustrations, and not much has changed in that regard.

However, to combat the frustration and disappointment of waiting six months just to get the couch of your dreams, I use our collective situation as an opportunity to give control back to you, the homeowner. I start by providing options.

You could either:

-

Wait it out for the delayed pieces you first fell in love with, or

-

Select new pieces you also love that will arrive much sooner.

It may seem like a no-brainer to put those options on the table, but framing the process in this way allows you to choose your own path in a situation that calls for a lot of sitting around, twiddling our thumbs. Instead of hoping things will be different, I want to give you a real shot at shifting the trajectory of your project.

But here’s the real secret:

I encourage the homeowners I work with to take advantage of the ability to source materials and pieces from unique American vendors.

This is a strategic move that can change the integrity of your home and save you time on shipping delays.

As an interior designer, it’s my job to operate on the front lines of this industry so you don’t have to do it yourself. But this role comes with perks, especially if I get to work with American-run vendors. Not only does this give you a wide selection of authentically crafted pieces that can last the test of time, but it also won’t come beat up in a shipping box fresh off the factory line.

In fact, using American vendors allows interior designers to contact the company directly and find out exactly where your piece is in the production process. No more guesstimating! That means accurate, real-time updates on delivery.

Buying furniture from companies that mass produce pieces sometimes overseas can result in an unreliable product and abrupt or unexpected cancellations in shipping. If you work with domestic vendors instead, an interior designer can build a personal relationship with the company and work some backstage magic you’d otherwise miss out on!

The Basic Bottom Line

COVID changed the game for pretty much any business owner you can think of, but I’m sure that’s news to no one.

In order to help the homeowners I work with thrive in this unexpected season of life, we are rolling with the punches. Here’s how:

-

I knew the options would be slim for homeowners, so I am manifesting options where they could be found, giving them control over the situation as best I could.

-

I am focusing on sourcing my clients’ products from American companies to cut down on shipping times and gain personal access to manufacturers.

-

I simply have stopped fighting the inevitable and let go of all expectations that this industry will go back to “normal” anytime soon. This has given me the freedom to do good business in a very different world than I started out in.

Whether you’re a business owner or a homeowner, I want you to know you’re not alone. This pandemic world is ever-changing, and I know how daunting it can be to keep up with the twists and turns.

But when we seek out and hold tight to the opportunities around us - no matter how difficult they may be to find - we can flourish in this unpredictable time.